Updated January 27, 2025

Healthy building initiatives often address safety issues such as carbon dioxide, carbon monoxide, and fire protection – as they should – but neglect Legionella and other waterborne pathogens that are responsible for a significantly higher number of hospitalizations and deaths. To have a truly healthy building, a comprehensive water management program must be implemented to control Legionella and other pathogens in the building water systems. It can make the difference between life and debilitating illness or death for the building’s tenants, patients, residents, visitors, guests, and staff.

What Makes WMP Implementation Inadequate?

So what does it mean for a WMP to be improperly implemented, or for processes to be inadequate? Many organizations attempt to address water quality problems by creating policies or “aspirational” documents or using templates which, while often well-intentioned, almost always lack specific and repeatable actions that are measurable, verifiable, or effective. Facilities often create these static documents for an audience of auditors, or simply to check a compliance box rather than to improve safety. Steps taken to prepare for auditor reviews could lead to some improvements but do not constitute a water management program. Written statements alone will not mitigate the risk of infection in building water systems.

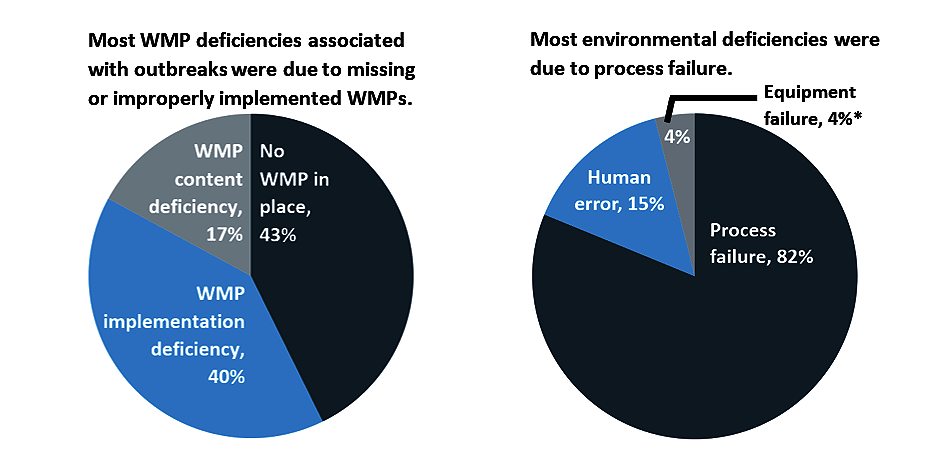

CDC data on Legionnaires’ disease outbreaks from 2015-2019 highlights the crucial differences between a document and an implemented process for ASHRAE 188 water management programs (WMPs). Finding 82% of environmental deficiencies were due to missing or inadequate processes, the CDC concluded that “all of the deficiencies associated with outbreaks could have been prevented by comprehensive, properly implemented WMPs.”

Images courtesy CDC

Noteworthy supplemental data with the CDC’s 2015-2019 outbreak review showed the following:

- 62.5% of sites that had a WMP did not have monitoring or targets documented or corrected.

- 37.5% of sites that had a WMP did not have flushing logs.

- 46.6% of the sites had no WMP at all.

The CDC’s supplemental data pointed out some specific deficiencies:

- No consistent tracking of water quality measurements

- Inadequate control (preventive) measures including ones needed to address biofilm, sediment, and corrosion

- Lack of corrective actions when targets were exceeded

- Responding to Legionella test results based on an overly simplistic or otherwise inadequate review of the data (e.g., considering only positivity)

- Inadequate documentation

- Inadequate communication

The water management program outlined in ASHRAE Standards 188 and 514 follows a process to address Legionella and other pathogens in building water and reduce the risk of infection to staff, guests, and visitors. Comprehensive and properly implemented water management programs have been shown to effectively minimize and control one of the most avoidable causes of death in commercial buildings: premise plumbing pathogens. A water management plan’s impact in reducing risk comes not from some talisman, binder, or document on a shelf, but rather from facilities and cross-functional teams taking concrete, consistent actions.

Digital Transformation for an Effective Water Management Program

Effective water management programs require a process approach in part because water is by nature a “process fluid” and remains dynamic throughout its journey. From source water to a municipal treatment plant, through networks of city piping, and finally to buildings and their associated miles of pipes, water is constantly changing during each part of this maze. Near undetectable traces of pathogens picked up in a network or grown in the biofilm can dramatically multiply in a building where the water is heated, its disinfectant levels drop, or it becomes stagnant. These changes require a process approach to minimize water quality variations that can be controlled.

Edwards Deming, the famous Professor, author, and management consultant defined process and quality best: “Quality comes not from inspection but from the improvement of the production process.” Testing and inspection will not improve the safety of building water without corrective actions and control measures that are continuously refined based on data collected in an actual water management program.

Water management programs require a team, and the program must manage the activities and responsibilities of each team member. Much like a conductor leading musicians in a symphony, coordination among internal departments and external partners is vital in managing building water. Team members must share control measure documentation and test results and work together to determine corrective actions needed.

With all that is required to successfully execute a water management program, automation is critical for ensuring proper process flow. Just as businesses and other organizations automate payroll, project management, and most other complex operations, water management programs are best executed with software that automates tasks, analytics, and reports. An efficient system for storing and finding pictures, corrective actions, targets, water quality data, and other data and documentation is also critical. The water management program software must be dynamic and flexible, providing notifications, reports, and analytics–almost like a virtual project manager.

In addition, having an integration that automatically populates the WMP with laboratory test results for Legionella and other pathogens speeds up the reporting and allows for robust analytics quickly, enabling a quicker response. It also reduces the chance of human entry errors.

Integrating IoT water quality sensors and flush sensors (e.g., with LAMPS Complete) provides more data, faster and more frequently. It also reduces the workload for facility personnel.

Do you have a comprehensive, properly implemented water management program – the kind that the CDC reported could have prevented all the deficiencies associated with outbreaks it investigated from 2015 to 2019? Just as you would not use a static binder or template to manage your organization’s finances, you should not trust the same for managing water quality, which affects health and life. For efficiency, competitiveness, and safety, many organizations are therefore replacing their binders with digital systems.

David Swiderski is the Senior Technical Strategist at hcinfo.com.

In answer to your question, a definition on google is:

a course or principle of action adopted or proposed by a government, party, business, or individual.

“the administration’s controversial economic policies

I go wit process. If you have a WMP as a doc and go no further – do not follow through with its parts – you are at increased risk of Legionella.

This is what the CDC says in so many words

David thank you for your comments! The chart at the beginning of the document is actually from the CDC so not only are they saying it but showing us.

it is a process not a document-you document your processess and results

Thanks, great comment Pat! At its root all good process work and quality control is based on PDCA (Plan, Do Check, Act) and continuous improvement!

It is obvious to those of us intimately involved in formulating or carrying out WMP’s that they are indeed a process and would prevent outbreaks if properly overseen. One major detriment to that which is largely overlooked is the understaffing of most Healthcare Facility maintenance departments. Even those that have a full complement of staff deal with constant turnover, lack of training time, and general deterioration of the knowledge level of workers. That fact makes proper WMP oversite impossible!

John thanks for your comments! The issue of turnover and understaffing is one of the reasons we try to not only have the WMP software but also provide a large number of online training courses and over a hundred training notes to get new staff up to speed. Several states are starting to also require ASSE 12080 in new legislation, it will be interesting to see much like other certifications in healthcare if this might help.

While I agree with your assessment concerning staff turnover, training, and loss of institutional knowledge in healthcare, I also question the premise that this makes proper WMP overate impossible. I work with both large and small facilities and the issues are always the same; lack of personnel, lack of time to manage the WMP, and lack of familiarity with the program. My solution is to manage their plans for them. We document their work, document sample results and water test results, review records, interview staff, and gently urge them when something is not being done, or something new needs to be added. This takes time and effort, but the clients appreciate it (and pay for it) and since 2019 not a single facility that we manage has had a negative audit finding based on our Water Management Plans.

By contrast, a facility that I do contract work for when they ask, self-manages their WMP and they have been written up by Joint Commission for WMP issues. Precisely for the reasons you state.

A water management program for domestic water distribution systems is indeed a process that has been ignored for too long, including legionnaires disease/legionella! Implementation of the WMP’s is the most difficult element to enact/enforce! Matt Freije is the number one researcher/publisher that I have been following for the last thirty years! He has provided the necessary information, to initiate the materials for outlining some of my continuing education programs for the Illinois Plumbing Inspector Association. I am a retired Certified Plumbing Inspector for the State of Illinois, as well as for the City of Chicago. I am also a Green Plumber. I am still on his email list.

Michael thank you for your comments, experience, and perspective on this issue.

I absolutely agree; unfortunately, what happens as these things evolve is that the regulatory folks are “satisfied” with the document and may look at the results of testing to some degree, but I also recognize that, in this world of competing priorities, it’s not always possible for this stay on folks’ radar, particularly if they are resource-challenged. I was really excited to hear Matt’s remarks about making the whole process simpler (if I have learned nothing else over the years, it’s that the simpler the route to compliance, the more likely compliance would be achieved in a sustainable fashion).

Steve thank you for your feedback! You bring up a great point about the competing priorities. Stay tuned, we are working on quite a few things which in the next few weeks will alleviate quite a bit of work of implementing a WMP and also increase the ability to make data-based decisions.

WMP is definitely a process!

Thank you for your feedback Laura!

Water chemistry parameters are constantly in flux which is why managing water quality can often be so challenging. As a result a water management plan is clearly a process which needs to constantly evolve to meet changes in water quality/chemistry. The growth of waterborne pathogens is often the result of neglect of a water system by those who believed that a water system would manage itself as long as these was a water management plan sitting on the shelf.

Great comments Russ! Talking with someone today they mentioned water should have a “best before” date stamp. Much of the food we have is overseen by the USDA or FDA (certified pure leaving the plants) but much like water if you heat it up and let it sit too long, someone is going to get sick or worse.

I could not agree more. This concept is fundamental. Worst case is when a facility has no plan at all, but in a way it is almost worse when the plan exists in a dusty binder. The ASHRAE standards, and CDC toolkit, explicitly build in the communication tools needed for success: a team, team meetings, and annual review and revision. Just as fire prevention and general plumbing practices have become second nature to facility management, the water quality management actions should become routine. For a truly healthy facility, they must be routine. The sampling should be a part of automated workflow scheduling; the management actions should be part of performance plans. When we reach that point, lives will be saved. Until then, lives are being unnecessarily lost.

Alicia thank you for your comments and there is great merit to your point “it is almost worse when the plan exists in a dusty binder”! I believe there is a lack of awareness not only about how all the deaths are avoidable, but also about many survivors’ stories which are more numerous, and in a way quality of lives lost which also is tragic.

Training of building managers or cooling tower operators is a prerequisite for any effective Risk Management Program. People have to be trained to identify risk factors related to cooling tower systems. Only then an effective risk management program can be written and implemented. I’ve written books and held seminars to fill this specific lack. Keep it in mind! Do you want to prevent Legionnaires’ Disease that can be transmitted by cooling tower systems? Get trained!

Mario thanks for your comments and insights!

A WMP is a process. This may be one reason why it is so prone to error. Because a checklist or a document fills up quickly. But to capture a process completely, to map it, and to be able to sustain it safely in the long term while taking finite resources into account (working time, personnel, financial budget), that requires a wide range of skills – especially those of cooperative collaboration with a preventive mindset. If things are viewed reactively, we may be lagging behind the essentials. But deficits from past years (e.g. poor or misunderstood maintenance) can usually not be remedied without effort. However, even in new construction projects and in early planning phases, hygienically critical errors are sometimes not recognised. Therefore, the right people are needed in the right places. The work never stops! Let’s get it done.

Thank you for your comments Dr. Leiblein!

I think it’s a process guide in which all of the process-steps need to be documented. As a first step re: a WMP, I’ve been recommending (via my annual report) to a particular client, that has an extensive plumbing system, to install pipeline identification…since 2017…still not completed!

I’ve discussed potential employee health/safety issues and legal exposure but, apparently, the corporate hurdles are impossible to overcome.

Mike thank you for your feedback. There definitely needs to be a balance between effort and cost vs. benefit. Staff and resources in most facilities continue to get cut or not replaced quickly enough. We have been working on automating as much as we can and simplifying our Water Management Program Software while still keeping control measures and corrective actions robust.